Founder's History

Home Founder's History

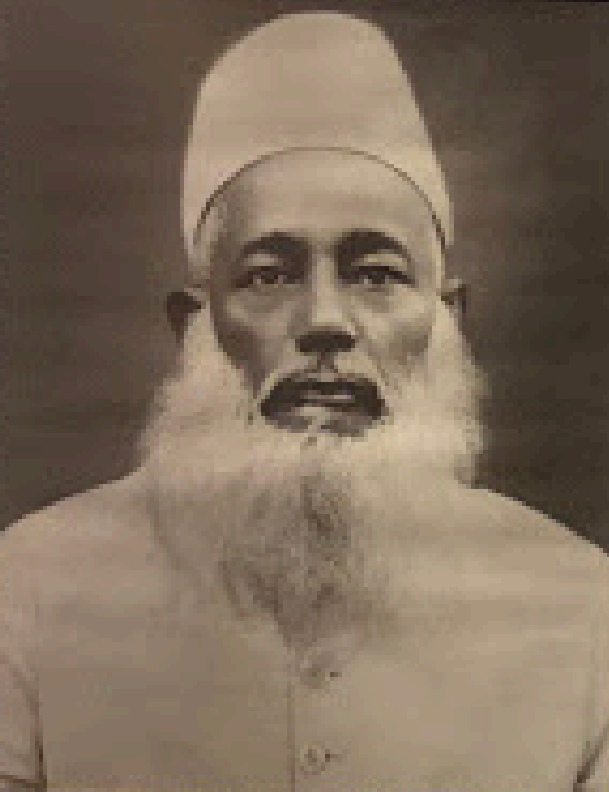

Mohamadali Tajbhai

Vahanvaty

Mohamadali Tajbhai

Vahanvaty

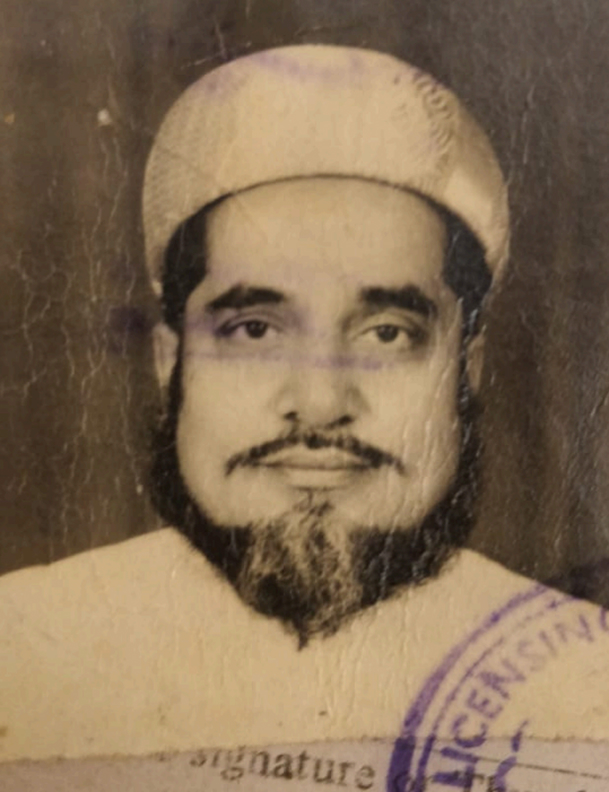

Esufali Mohamadali

Vahanvaty

Esufali Mohamadali

Vahanvaty

Sheikh Ali Asgar

Esufali Vahanwala

Sheikh Ali Asgar

Esufali Vahanwala

Sheikh

Khozem Vahaanwala

Sheikh

Khozem Vahaanwala

Ship Breaking business at Gujarat

Steel rolling mill Taj Iron and Steel Works Ltd at Wadala Mumbai

National Cotton Textile Mills Ltd at Mumbai

Modernisation of steel mill at Mumbai

Established Electroplating at Panvel Navi Mumbai

Establishment of electroplating job work shop SaifyIND at Bangalore

Won appreciation award from Sundaram Clayton Moped Division.

We worked as distributors for Electroplating Chemicals and provided technical service and expertise all over South India.

Set up a Zinc plating line in Loutolim - Goa in 1993 till 2004.

India's first White Bronze plating process established for Telecom Connectors.

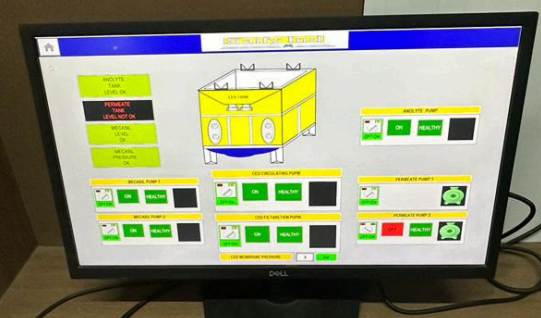

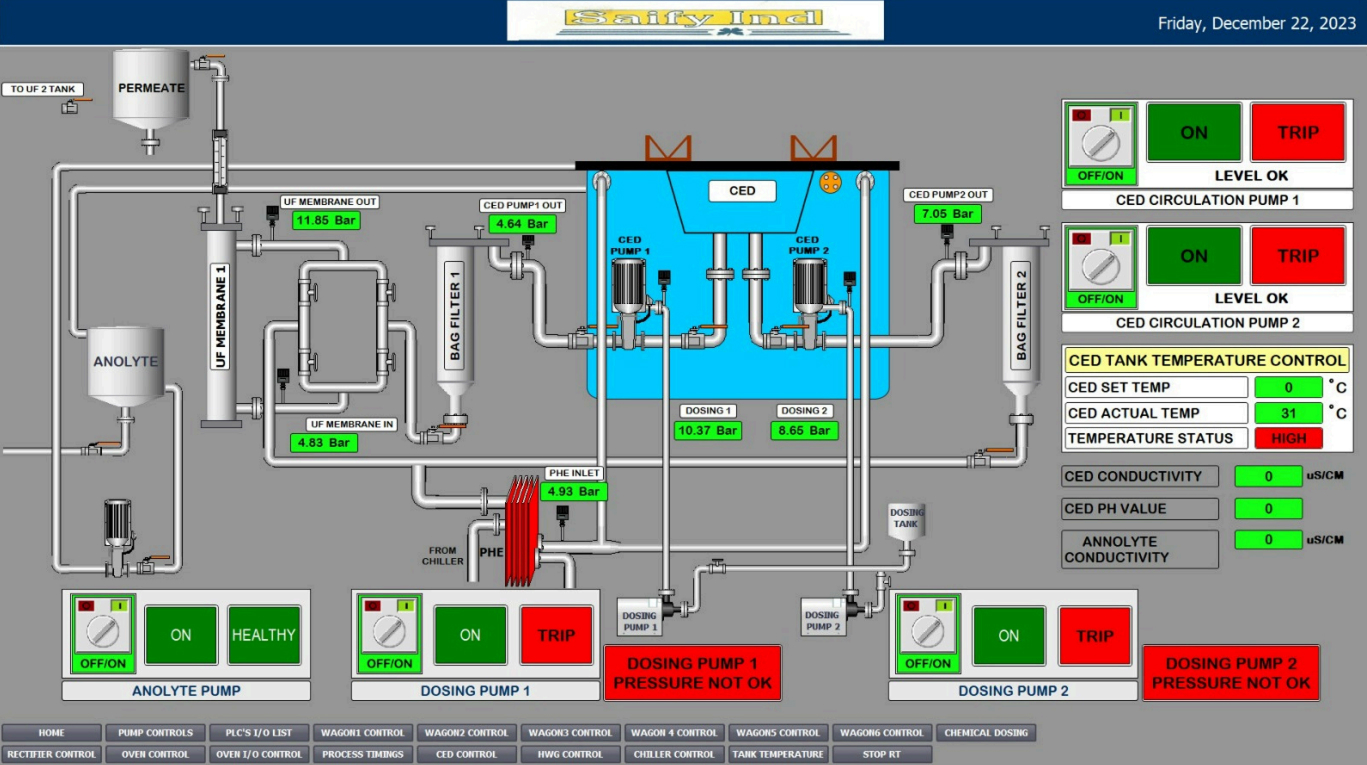

CED Plant for Saify IND Attibele

Established Copper plating line for Connecting Rod for TVS/Two stroke engines.

Zero discharge of Water from all plants.

80% Process Water Recycling with state-of-the-art Water Treatment facilities.

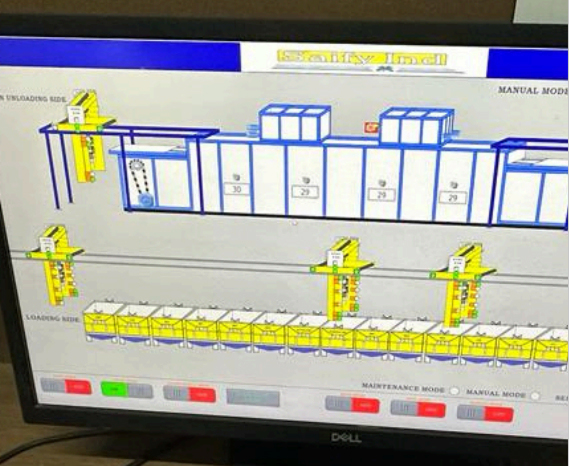

Seven Automated lines with SCADA in all for Zinc Rack and Barrel Plating.

Established a Zinc Iron Plating line approved by Volvo.

Dedicated line for Zinc plating of Fuel filler line with internal and external Zinc plating.

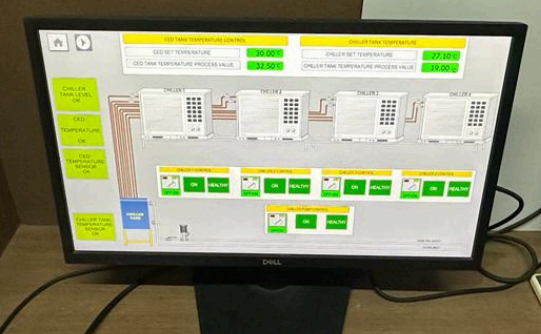

Three lines of CED Coating totally coating 4500 Sq metres/day, running at Saify plants all built in-house

Best Appreciation Award - From Toyota Boshoku

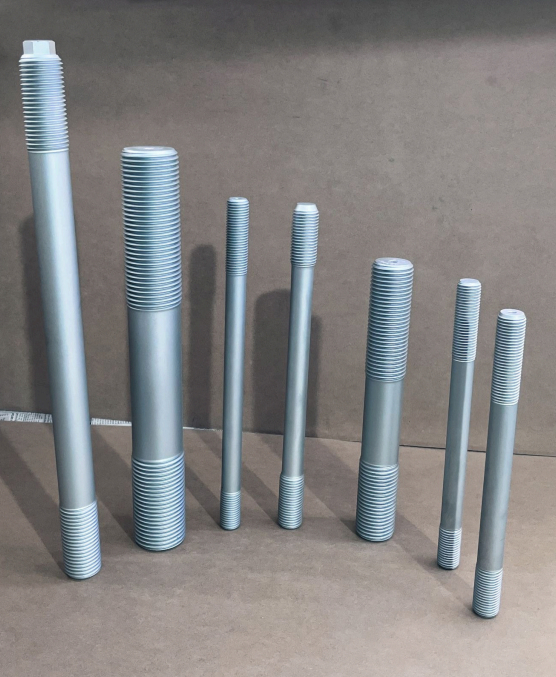

We developed 6 Dip Spin SPMs & 6 Spray Coating SPMs developed for Zinc Flake application. Dip Spin machines with individual racking for sheet metal components. Indias largest capacity plant for critical Wind Mill fasteners of 8.8 and above hardness. Nacelle, Rotor Blades, Foundation and Tower Components. Dip Spin for Chains with complete internal coverage in links and pins. 1500 Hours SST with integrated COF lubricants.

From 2010 to 2019 received several awards from Toyota Boshoku, Toyota Toyotetsu for On time Supply/Cost reduction/ Appreciation and Quality Targets.

Achieved SQ Mark certification from HMIL for Zinc Nickel Plating for brand new plating line at Plant III

Set up internal Plant Building and infrastructure team.

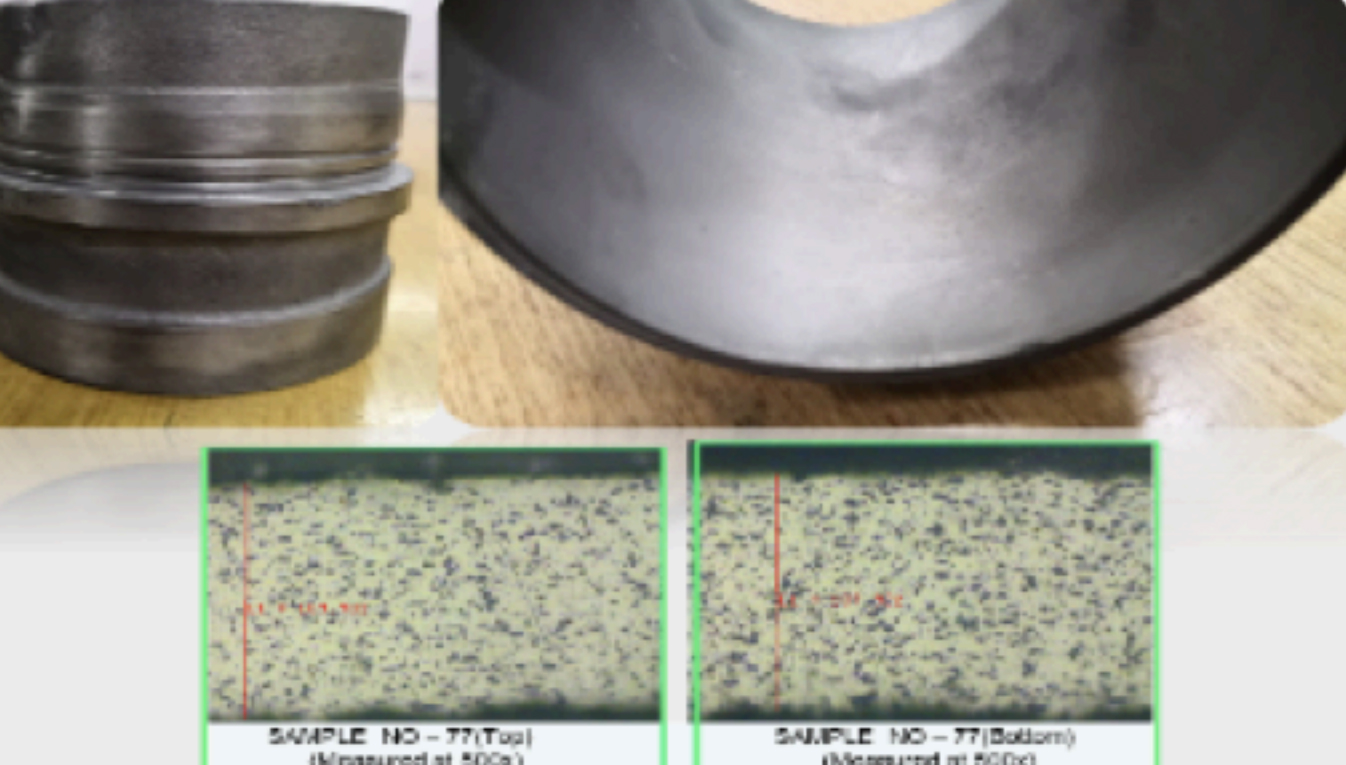

Developed Nikasil (Nickel+Silicon Carbide) Plating for Aluminium Engine Blocks for Air Compressor and Motorcycle Engines.

Hard Chrome Plating Line for Saify IND - HMSI

Best Delivery Award - From Stanzen Toyotetsu India

Mechanical Zinc Process

Built a Hard Chrome plating line for Exedy/Honda critical clutch parts

Partial internal Electroless Nickel plating of Clutch Plate Spline Hubs.

Two Lines with SCADA for Manganese Phosphate Coating/ one line for Zinc Phosphate Coating.

Toyota Boshoku conducted in-depth 6 months training programme for Robotic Painting of Plastic Car interior parts.

Electrostatic Spray Zinc Flake Coating for CRDI Common Rail bodies for Bosch.

Established Zinc Iron Plating Line - which received Best Development Support

Award From Schaeffler

Conveyorized Zinc Flake Curing Line - received Best Kaizen Award from SFL.

Dedicated CED line for Toyota/Suzuki Chassis is established at Harohhalli.

CED Line established at Plant V in Harohhalli, catering to KIA-Mobis

REY CED and Topcoat painting line built for 3 and 4 Wheeler Body Panels, Electrical Enclosures, Machine Tool Enclosures, and Large Sheet Metal Assemblies at Maloor.

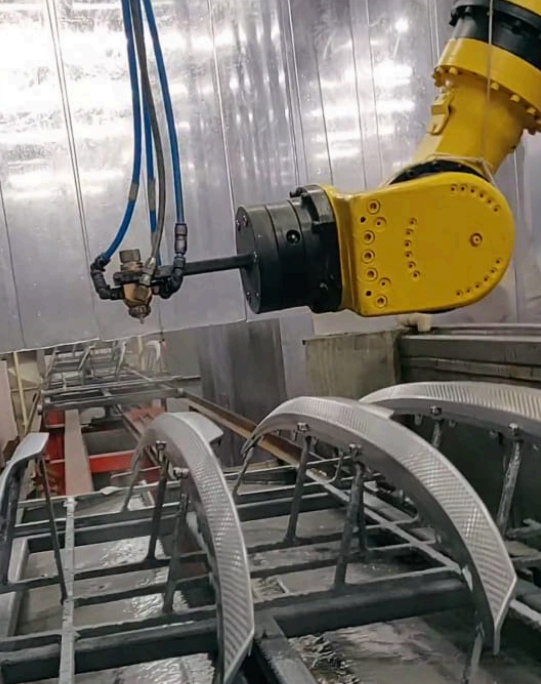

CED Coating and Robotic Painting line being set up at Guddipalli (near KIA).

Line 2, Black CED Coating + Black Powder Coating at Harohhalli - Additional capacity for KIA

Grinding and Machining Project at Plant 4, Bommasandra, for Front Fork Inner Tubes

We are presently SQ Mark certified Painting Vendor to KIA Motors Tier I Suppliers.